- Pictures with Words

- Posts

- Securing Fasteners

Securing Fasteners

Methods to Eliminate Wondering and Double Checking

Lock wire, or safety wire, the names seem to be interchangeable, gives me peace of mind. I don’t wonder, “Did I torque the drain bolt?” Or, “Could that drain bolt vibrate loose?” Safety wire is required by some groups, depending on what you are doing.

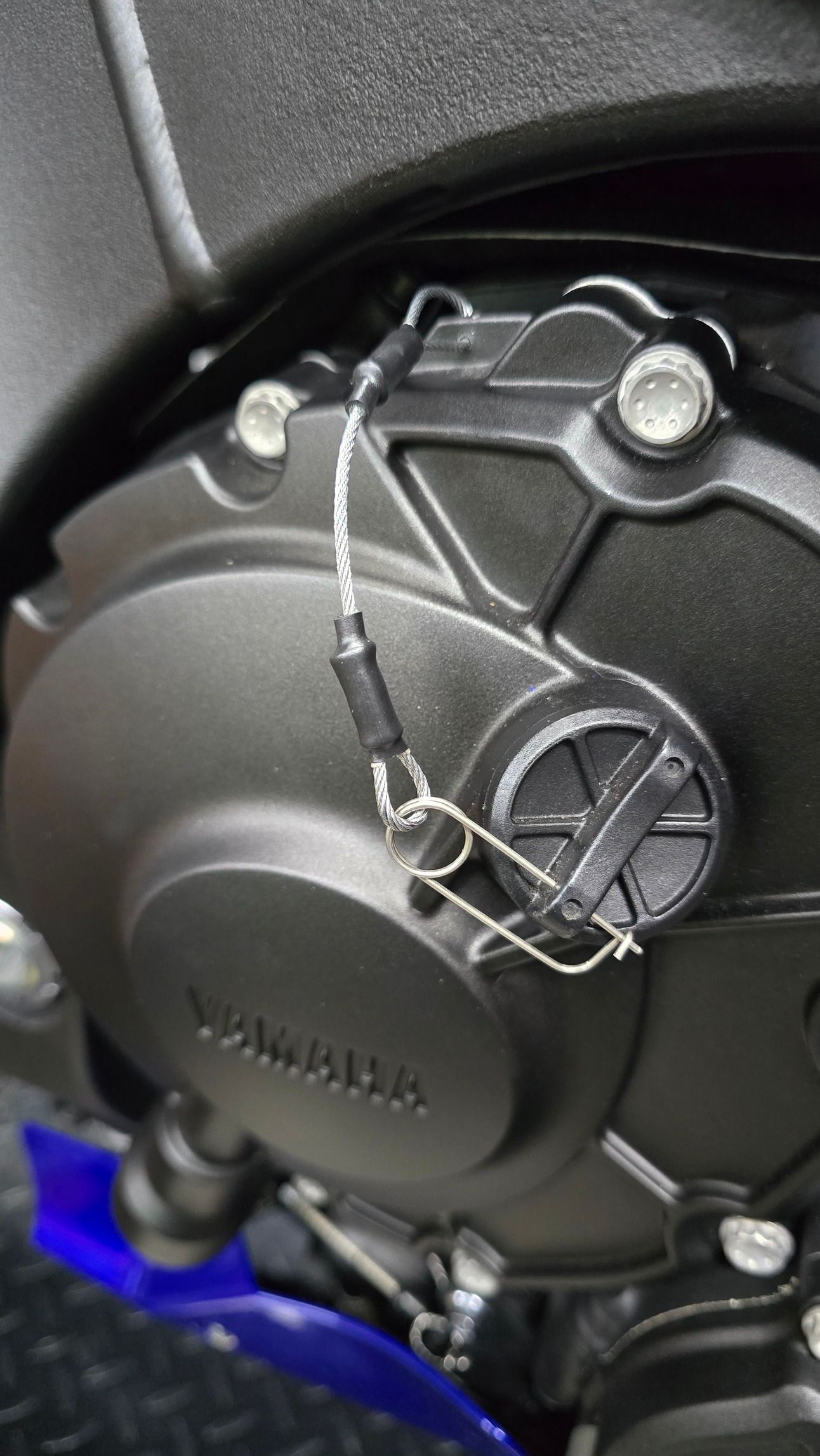

Safety wire securing the oil filter cover on my KX450.

Torque Seal is another process that reminds you that a bolt has been torqued. Now of course, this means you have to remember to apply the Torque Seal after the bolt is torqued. I usually use torque seal on bolts that are not drilled for safety wire or are too difficult to drill for safety wire. Such as a button head bolt.

Button Head bolts with yellow Torque Seal.

Multiple colors to choose from.

This process lets me know which bolts have been torqued and which haven’t. Seems pretty obvious if it’s only a few bolts. But if you are working on a project that takes days, weeks or even months. When you can’t remember what you had for lunch the other day, it’s really nice to know which bolts have been torqued; when you have time to return to your project.

I liked the orange Torque Seal when I started, because it really stood out. But if you don’t have an orange KTM, it stands out too much. I’m not saying the Torque Seal color has to match your bike, because blue Torque Seal on a black bolt is really hard to see. But it is nice to have a color that is noticeable up close, but doesn’t stand out from a distance. For me, this is the white and yellow Torque Seal.

My track bikes get the oil changed frequently. So frequently that I’m getting tired of cutting the safety wire that I just installed. So, I have started to install a permanent, removable (oxymoron) solution. Using a 1/16th inch stainless wire rope and a crimped ferrule attaching a safety pin to the bike.

Safety Pin secured to the bike using a 1/16th in stainless wire rope and a couple of crimped ferrules.

Safety Pin securing the R1’s drain bolt.

Since the engine cases are painted black, I used some heat shrink to keep the ferrule from scratching the painted cases, when securing the oil fill plug. (Why do they have to paint aluminum black? Once it gets scratched, the contrasting silver color sticks out like a sore thumb. Topic for another time…)

A couple of things I really like about the wire rope method.

It’s fast to remove and fast to install

I don’t have to wear eye protection. The thicker safety wire has dangerously sharp ends and in the process of twisting it, those ends seem to always fly around in your face.

Again, the ends of the thicker safety wire is sharp. Watch your fingers and pick up the scraps from cutting it loose from the bike. Those scraps could easily puncture a bicycle tire or your pet’s paw.

I would like to use this wire rope method on the track bike’s brake caliper bolts, next. The brake calipers have to be removed each time you have to remove the wheel, to put on a new tire. Those bolts currently are not safety wired, just a dot of Torque Seal. But I would like to get some pre-drilled brake caliper bolts.

Edited, April 20th, 2025. No update.

Reply