- Pictures with Words

- Posts

- Poor Lawn Mower

Poor Lawn Mower

Newsletter 11.1 (Edited)

My dad handed down his old lawn mower when I moved into my current house, ten years ago. It was five years old at that time. My wife and I have used it every summer since. Purchased the Toro oil, filter and spark plug kit, probably every year, except for the last couple of summers. These last couple of years I was hoping it was going to blow up. It has acquired so many band-aid fixes to everything but the engine. It started up every year without a problem. Even still, we were ready for a new lawn mower. It would shake, rattle, lose specialty bolts for the handle and the front wheels won’t turn backwards. I bought a new Toro this year. And I thought it would be fun to put this one to rest. Well, I tried…

I ran the old Toro for ten minutes to get the oil hot, and then, drain as much as possible. In this fist video, I have already drained the oil and tied the “auto-shut-off” lever to the bar, so the engine would run continuously.

It ran for about one minute, forty seconds. Did you notice the blue smoke coming out of the oil dipstick tube? I left the dipstick in the jug that contained the removed oil.

I knew for sure I wasn’t going to be able to pull the starter cord. But I checked anyway, just to see how locked up it was.

But it wasn’t. Wait a minute. What’s going on? I thought it stopped running because something and another-thing friction welded themselves together? I could pull the starter cord several times. In fact, it actually sounded like it wanted to, RUN?!?!

So, I poured the oil back into it, inserted the dipstick, and gave her a yank.

No way, just no way. But Yep! It runs. I stopped it intentionally after a moment of running. Ok, so this time I poured the oil back out again. Now let’s see how long it runs.

It was really smoking this time towards the end. Now it’s finally locked up! I can’t pull the starter cord.

I called my dad to give him the news. He asked me, “What do you think locked up?” I have no idea.

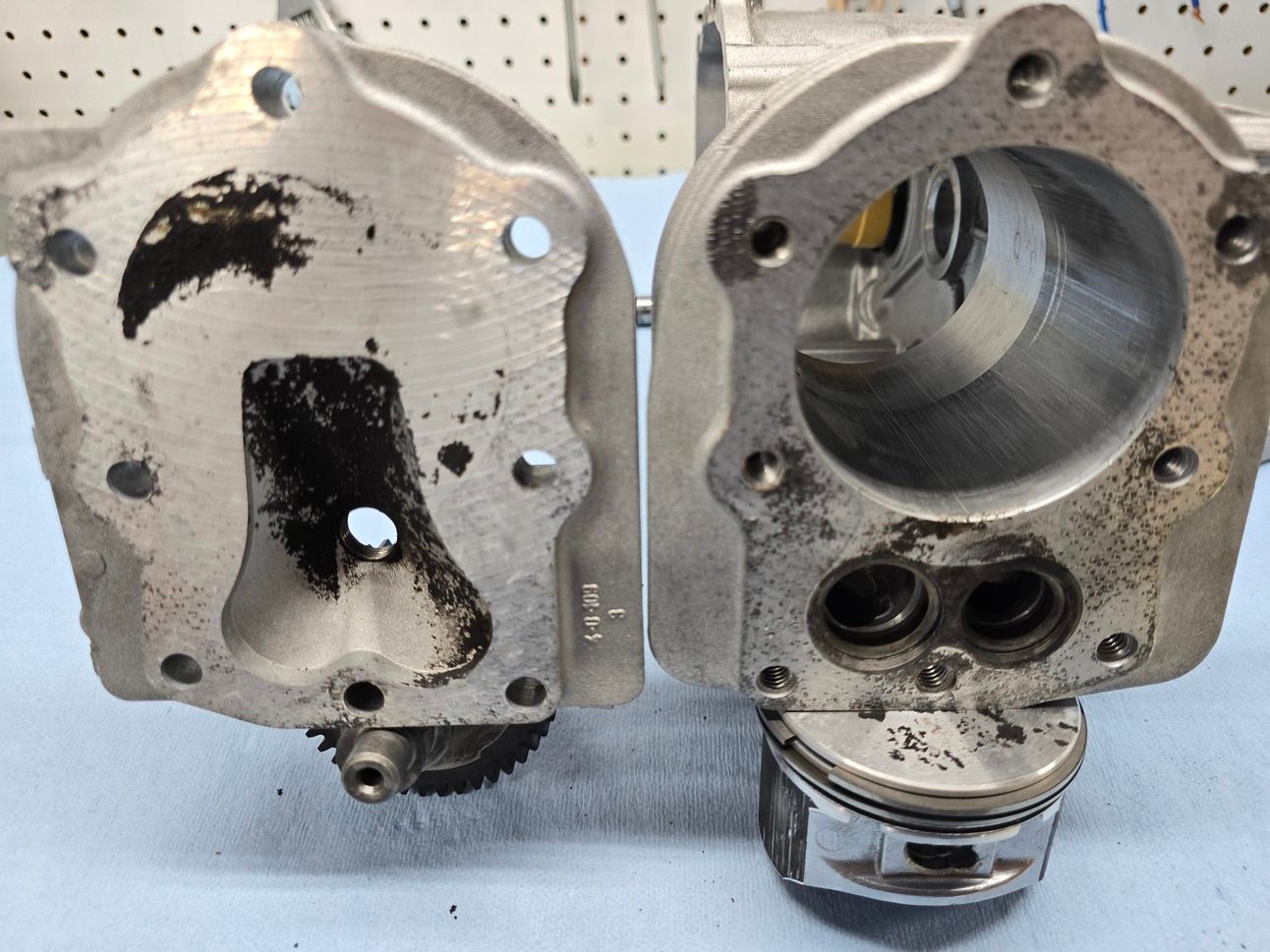

But let’s see. After pulling the engine apart and putting the examined pieces in the ultrasonic cleaner. I took some pictures to show you.

Wow, lawn mower pistons have a coating of Dry-Film Lubricant on their skirts!? Even 15 years ago!? There is some scraping on the piston skirts. I’m not exactly sure if that happened without oil or during its lifespan.

Fancy-pants piston. More like fancy-skirts.

Spark Plug looks good.

Valves and Lifters look good.

Camshaft Lobes are good.

The Crank Pin Journal looks bad.

The big end of the Connecting Rod looks horrible. The small end of the connecting rod looked good and so did the wrist pin.

The Cylinder Wall is not great. But not too bad either, considering…

Notice where the two piston rings stopped, right at Bottom Dead Center. And it looks like some metal was transferred. This is one of two places where the piston comes to a complete stop (Top Dead Center and Bottom Dead Center). Must it have stopped long enough to weld the rings to the plated cylinder wall?

I did notice that when I was removing outer parts of the engine, that the crankshaft could turn. Here we go again. Let’s put this thing back together, fill it full of oil and see if it runs? Just kidding. But the fact the crankshaft could turn again led me to believe that it could run again. Maybe not great, but maybe it could?

I wonder what broke free? The rings from the cylinder wall or the big end of the connecting rod? Both?

Is this a mechanical version of what they call, “Limp Mode?” Just let it cool down, pour in some more oil, and you should be able to finish the lawn. LOL. Also, is this a benefit of having aluminum bearings and a steel crank pin? If it were steel on steel bearings, would it truly friction weld itself together? The crankshaft never stops, unlike the piston and its rings.

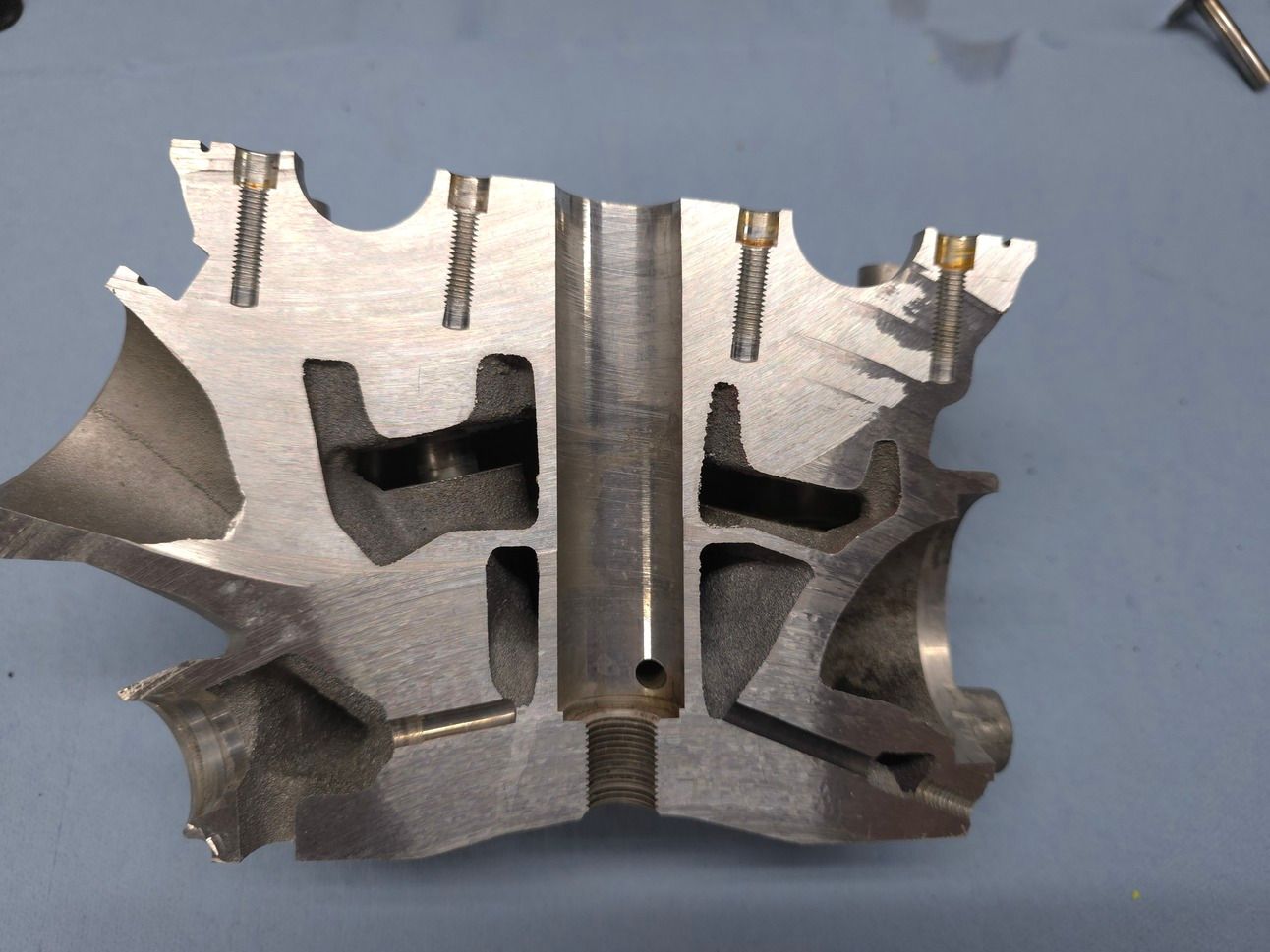

This reminds me of the time my dad and I bought a Honda RC51. The bike ran. But when I checked the valve clearances ahead that coming track season. I found this:

RC51 Camshaft bearing cap. Plain bearing, a steel camshaft journal, riding on thin film of pressurized oil with an aluminum housing.

One of the previous owners, there were many. Installed the front cylinder head camshaft caps backwards. They have arrows on them. It would be assumed that the arrows would point forward, which makes sense. However, if they had used a service manual, preferably the OEM. They would’ve known the arrows points towards the intake (pointing backwards on the front cylinder of a v-twin.) Since that front cylinder head, and caps, were scrap, I decided to cut that cylinder head in two pieces to see the water jacket passages.

2001 RC51 front Cylinder head cut in two. Notice they drilled in two places to connect the water jacket passages.

Reply