- Pictures with Words

- Posts

- Matching Shapes

Matching Shapes

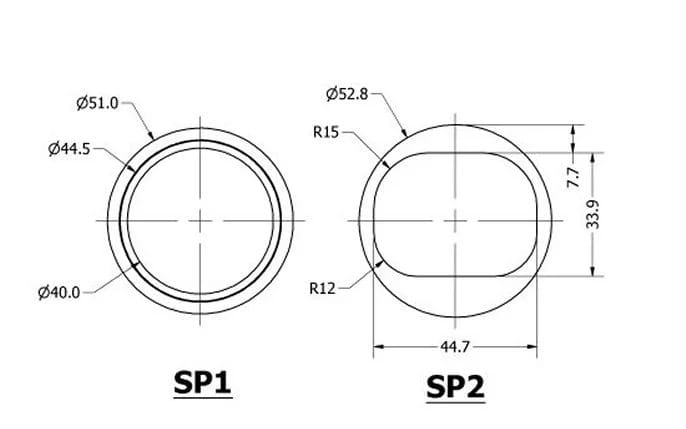

There are two generations of the V-twin RC51, the SP1 (2000-2001), which I have. And the SP2 (2002-2006). Among other small changes, the SP2 has D-shaped exhaust ports, where the SP1 has circular exhaust ports. Each with matching inlets for the stock headers.

Header inlet dimensions. Photo copied from Speedzilla.com (forum)

It’s next to impossible to buy a SP1 slip on exhaust. Which means, it is possible, although there’s only a couple options and not very desirable. My SP1 has a SP2 header installed from one of the previous owners. This allows more options and some desirable options. Owning a SP1 engine (and bike), with a SP2 header, that’s just too much blockage for a slightly OCD person. I’m not looking for a tenth of a horsepower, but I am looking to get them to match.

SP1 header inlet on the left and SP2 header inlet on the right. Photo copied from Speedzilla.com (forum)

I’ve had a set of SP1 headers sitting in my garage for several years now, waiting for this day to come. I am going to cut off the inlet (singular, explain later) and weld it onto the SP2 headers.

SP1 (left) and SP2 (right) headers. Note the detachable rear cylinder header parts, which attach to the hole pointed directly at you on the bottom of the photo. A two piece design for the SP1, which I have connected to a SP2 header. And the one piece design for the D-Shaped. Also, note the different angles of the header outlets (bottom of the photo, towards the floor). Photo copied from Speedzilla.com (forum)

Notice the cut line I placed on each header is nowhere close to the same location. This intentional misalignment allows for extra material and room for mistakes.

I have a one and three-quarter inch pipe clamp (taking band) coming. This specially designed clamp has areas removed from the middle so you can tack weld the pipes perfectly in line.

Tacking Bands. SS Custom Engineering (sscustoms.com.au) Photo by SS Custom Engineering.

I also had a dual argon regulator come recently for this project. And some purge plugs, which I’ve had for as long as those SP1 headers have been sitting in the garage.

Dual regulator for the argon bottle. One for the shielded gas of the TIG welding torch (outside of pipe) and one for the shielded gas supplied to the purge kit (inside of pipe). Blue purge kit installed on the scrap header pieces as an example. One end (metal adapter for plastic tube) supplies the argon and the other end has a hole to allow unwanted gases to escape (mesh filtered end on the pink).

I have a couple of polls for you to participate in, if you wish:

Reply