- Pictures with Words

- Posts

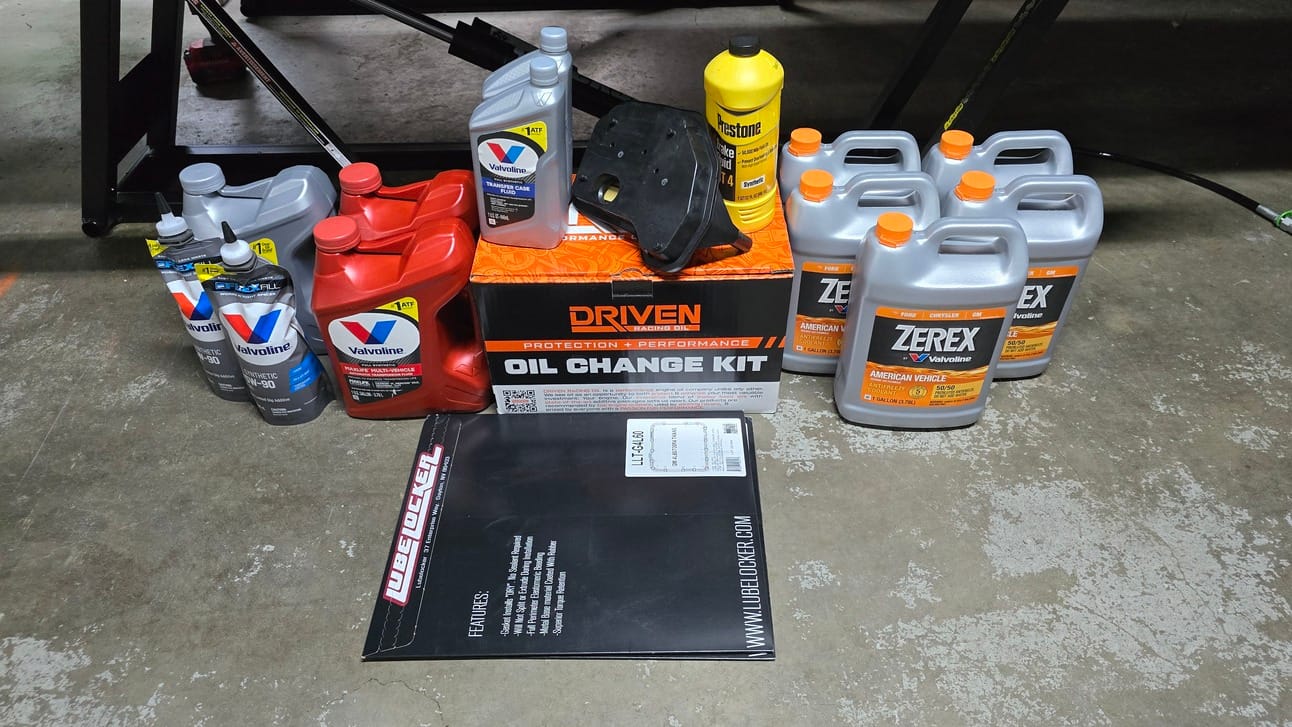

- All Fluid Change

All Fluid Change

Everything in life needs to be maintained, the more things you have, the more things you have to maintain.

I recently performed an all fluids change on my truck. Except for the power steering fluid, it got changed last year when I replaced one of the power steering lines. So everything else would be, engine oil and filter, brake fluid, transmission fluid and filter, front and rear differential, and the transfer case. For the smart-asses out there, all the local auto parts stores were out of blinker-fluid. Weird, I know…

If you ever changed the transmission fluid on a transmission without a drain plug in the pan, you know that it gets messy quick, no matter how large of a catch can you have. I didn’t have time to order a pan with a drain plug, better yet, I didn’t think far enough ahead to see if my current truck’s transmission pan had a drain plug. With everything dripping, draining and splashing all over my garage floor, that’s what it felt like, most of it was actually in the catch cans. It was time to put in the drain plugs and fill things back up. Everything was going smoothly, until. I put in the transfer cases’ drain plug and torqued it to 13 ft-lbs and then the fill plug and torqued it to 13 ft-lbs. Good job, but there’s a step missing in there. What about the transfer case fluid? Damn. I’ll just remove the fill plug and put in the transfer case fluid, easy enough. So, I start to loosen the fill plug, but it feels like it’s getting tighter and tighter. Wait a minute, am I going the right direction? Yes. So I proceed. However it’s still getting tighter and tighter. OK, I’ll bust out my half inch drive ratchet. Using quite a bit of strength, I was able to remove the fill plug. Wanna see a picture?

With the fill plug removed, I immediately got frightened, “What about the drain plug? If it starts to get tighter I’m just leaving it. And deal with it next time.” But, the drain plug loosened just like it should. Wheh. There was probably about a half hour of laying underneath the truck of no movement; except for the mind. It was racing, “What do I do now? How am I going to fix this? Please don’t say I have to use some shady method of a temporary fix.”

After collecting my thoughts, I noticed that this was an aluminum fill plug going into the aluminum transfer case. Which led to remembering when I got introduced to galling when working at SAFE Boats. What is galling? My definition is: When the male and female threads weld themselves together. Here is a more formal definition: https://en.wikipedia.org/wiki/Galling. SAFE Boats used a lot of stainless because of corrosion from water and especially, salt water. The first time I put any force onto a bolt at SAFE Boats, I said to my boat lead, “It won’t go in any farther, it’s stuck.” He replied, “Did you use anti-seize?” Oops! We had to cut that bolt and nut, and start over. In my experience galling is more prone on softer metals such as aluminum on aluminum and stainless steel on stainless steel. Luckily on motorcycles it’s mostly a steel bolt with aluminum female threads. Although, I usually use anti-seize on the hardware that is exposed to the elements. On a motorcycle, that’s most of the bolts.

Although I don’t think this caused the problem, there was some type of sealant on both of the drain and fill plugs when they were initially removed. So I removed the old sealant and applied new RTV (sealant) before installing.

My solution was to chase the female threads and find a bolt for the fill plug. To make a long story short(er). The plug size is an M16×1.5. My thread chasers only go up to an M14, but thanks to the very large Napa store in Kent, next to IKEA, I now have an M16×1.5 tap. Using a tap is NOT the way you clean up threads. I learned this in my Mill and Lathe class at Green River Community College. A tap is for cutting threads and a thread chaser is for cleaning up and restoring threads. The problem with using a tap to clean up threads is, there is a high risk of cutting the threads deeper and thus enlarging the hole. Since I could only find a tap locally and a chaser would have to be ordered, I proceeded with using a tap. The other risk, getting aluminum chips into the transfer case. So, I cut a little bit with the tap, then removed it, cleaned it up with a rag, re-lubed the tap and repeat.

No, that’s not blood. It’s transfer case fluid used as cutting lubricant.

Not great, but good enough to be a permanent fix.

I found an actual automotive plug (M16×1.5) with a sealing washer at Ace Hardware. Since the drain plug was good, I removed the RTV that I applied previously and anti-seized the heck out of it. Installed the drain plug and torqued it to 13 ft-lbs, pumped in the transfer case fluid, and installed my new steel fill plug from Ace Hardware, and torqued it to 13 ft-lbs.

All buttoned up. See, there’s fluid in there, lol.

Everything else went smoothly and all fluids have been changed. For those who may be asking, “Why do the fluids have to be changed?” Fluids have to be changed because heat over time destroys the lubricating ability of the fluid. When there is no more lubricating ability, you wear out your engine, transmission, differentials, t-cases, etc. Five to ten thousand dollars in repairs, compared to a couple hundred dollars for all fluids. Lack of maintenance is the number one reason why most vehicles are in the shop.

What caused the galling? Was it really just the aluminum on aluminum? If that was the case, then how come the drain plug didn’t gall? Did I cross-thread the fill plug? I always start a bolt by hand. But that doesn’t mean I didn’t start cross-threading it by hand.

Reply